Hydraulic fracturing dominates much of the United States’ energy production currently and has been a major factor in the ability for power plants all over the nation to phase out coal, one of the dirtiest fossil fuels to burn. However, much like the name suggests a hydraulic processes utilizes fluids in order to extract natural gas from the shale buried deep below the Earth’s surface. Not only is water, mixed with sand and other chemicals, utilized in the process, but it is also a byproduct from releasing the natural gas from the hard rock. In fact, the amount of fluid that returns to the surface is a larger volume than what is injected into the well. As many in the industry know all too well, the fluid that is returned to the surface can’t simply be funneled into a stream or left to soak into the ground. Regulations require that frac fluid be collected and disposed of in approved manner. While there are many different options when it comes to frac fluid disposal, it can be hard to find the best fit for your fracking company and the environment. From fracking ponds to water treatment options, we want you to be able to understand what your options are and the pros and cons of many of them. Perhaps as technology changes, there will be even more environmentally friendly and approved options available to the fracking industry over the next decade.

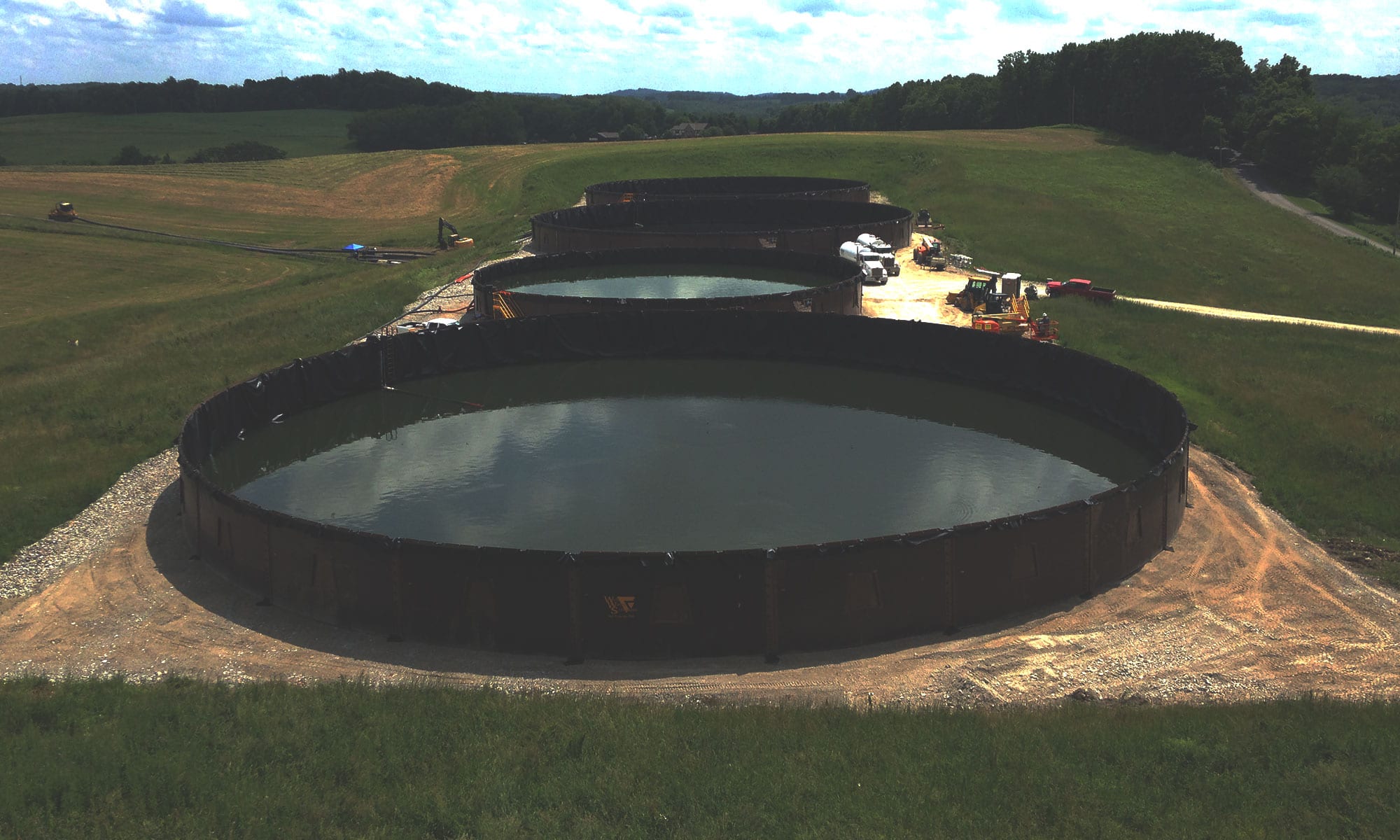

Fracking Pond

A traditional fracking pond is basically a hole dug in the surface of the ground. Many companies will dig frac ponds on site near the well in order to easily dispose of frac fluid right there on the property. The main difference between a frac pond’s construction and a man-made lake is that the frac pond is lined with thick plastic in order to keep the fracking fluid from seeping down through the dirt and into water tables. The convenience and affordability have made fracking ponds an appealing option for fracking companies, however, they do have their drawbacks. Fracking ponds can overflow if there are strong rains or snows, they cannot be moved, and they are almost impossible to set up with a heating system. These three problems can easily cause issues with drinking water contamination, land management, and even completely remove the option to treat the frac fluid if it does not remain heated.

Above-Ground Frac Tanks

Above-ground frac tanks take the basic idea of a fracking pond and modifies it to provide many additional features. Instead of being built into the ground, above-ground frac tanks are made with highly durable plastic with an assembled frame. This system allows you to attach a variety of piping, heating systems, or other necessary processes you may need to run a competitive, high-quality facility. Additionally, once you’re done with the frac site, your above-ground frac tanks will break down easily and be able to move to another site if needed, instead of leaving a hole in the ground that will need to be filled

Wastewater Well Injection

Another common disposal technique is to utilize wastewater wells and inject the fracking fluid back into the ground, deep beneath the surface of the Earth and below the water tables. While it seems like a logical idea to put the radioactive isotopes and brine back where it came from, there is one tiny problem. While fracking has shown virtually no correlation to causing man-made earthquakes, injection wells have a higher rate of doing just that. While still significantly insignificant, earthquakes caused by injection wells and the disposal of fracking fluid has been shown to occur. What’s more is they cost much more to provide upkeep on and service even though it may seem like the most permanent solution for fracking fluid right now.

Reuse

More and more fracking companies are turning to a new best practice for much of the fracking fluid, flowback, and formation water. As this fluid returns to the surface, it is collected in frac tanks, stored, and then reused. As much as 70 percent of fracking fluid on a frac site will be reused during the lifetime of the well, and while that is a huge industry change, that still leaves 30 percent without ideal solutions. Above-ground frac tanks allow for the evaporation and preparation of fracking fluid for cleaning, so maybe the best solution is that whatever isn’t reused goes to the final option and that’s wastewater treatment.

Water Treatment

Companies like Waste Water Solutions provide fracking companies with the ability to send fracking fluid, flowback, and formation water to be processed at a special facility that can purify the water to meet the highest-quality standards. This means that water is processed to remove all brines or salts, radioactive isotopes, chloride, and bromide, among other substances and the disposal of sludge is also left up to the processing company, making taking care to meet regulations for your frac site simple and affordable.